The Ultimate Overview to Expanding Life-span: Undercarriage Parts Maintenance Made Easy

The Ultimate Overview to Expanding Life-span: Undercarriage Parts Maintenance Made Easy

Blog Article

Make Best Use Of Efficiency With Long Lasting Undercarriage Components

In the realm of heavy equipment and equipment, the role of undercarriage parts is extremely important in making sure ideal efficiency and durability. The efficiency and efficiency of these parts can dramatically affect the overall procedure of machinery, making the choice of durable undercarriage parts a critical choice for drivers and supervisors alike. By discovering the complex partnership in between toughness and performance in undercarriage parts, a much deeper understanding of the subject emerges, clarifying the pivotal variables that drive functional success. As we browse through the intricacies of undercarriage maintenance, part, and longevity choice, a comprehensive expedition waits for to reveal the vital methods for achieving peak efficiency in sturdy applications.

Advantages of Utilizing Long Lasting Undercarriage Parts

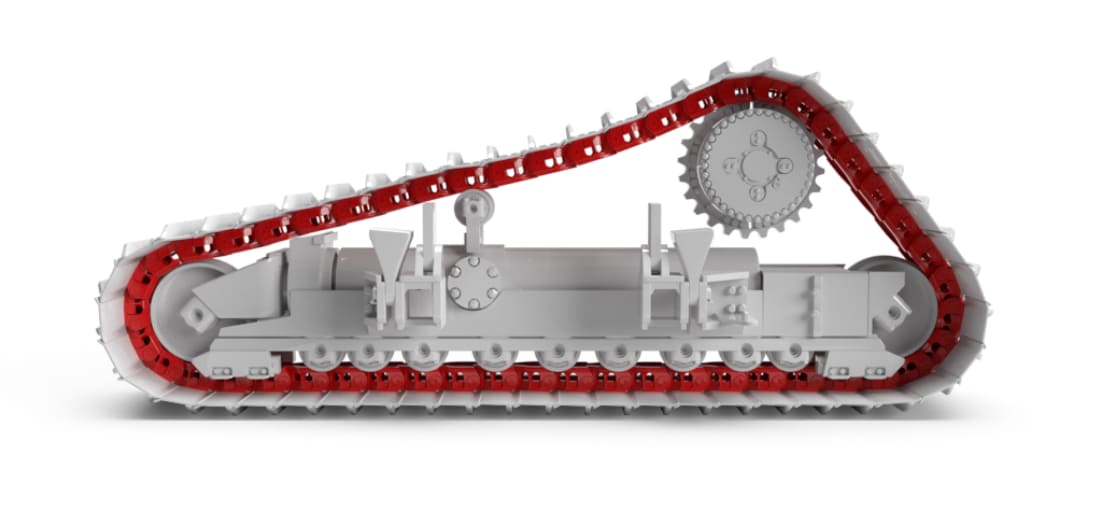

Using sturdy undercarriage parts not just boosts the long life of heavy machinery yet likewise reduces maintenance expenses considerably. By purchasing high-quality undercarriage components, such as tracks, idlers, rollers, and gears, tools operators can experience increased uptime and enhanced total performance.

Additionally, the long life of hefty equipment is straight linked to the quality of its undercarriage components. Sturdy elements can withstand the roughness of requiring applications, ensuring that the equipment remains operational for extended periods. As an outcome, drivers can prevent expensive downtime and upkeep expenditures, ultimately optimizing the roi for their equipment.

Variables Affecting Undercarriage Resilience

The durability of undercarriage components in heavy equipment is affected by different crucial variables that straight influence efficiency and longevity. Among the crucial aspects affecting undercarriage resilience is the quality of materials used in production. High-quality materials, such as solidified steel, are necessary for standing up to the extreme conditions and heavy loads that undercarriage parts go through. Correct upkeep methods additionally play a crucial role in determining the life-span of undercarriage elements. Normal evaluations, lubrication, and prompt replacement of worn-out parts can significantly prolong the sturdiness of the undercarriage.

In addition, environmental elements can have a considerable effect on the long life of undercarriage parts. Exposure to unpleasant products, severe temperatures, and severe working conditions can accelerate wear and tear on undercarriage components. As a result, picking undercarriage parts that are specifically designed to endure these ecological challenges is vital for ensuring durability.

Furthermore, the layout and design of undercarriage parts have a direct influence on their durability. Parts that are created to distribute tons evenly, decrease friction, and reduce tension concentrations are extra likely to have a longer life-span - undercarriage parts. By thinking about these vital aspects, tools drivers can maximize the sturdiness and efficiency of their undercarriage parts

Upkeep Tips for Lengthening Undercarriage Life

Applying routine upkeep regimens is necessary for prolonging the life expectancy of undercarriage elements in hefty machinery. To prolong the undercarriage life, it is important to frequently check for deterioration. Routinely examine for loosened or missing bolts, damaged rollers, or misaligned tracks, as these problems can escalate and trigger further damages if not attended to without delay. Furthermore, make sure that the undercarriage is appropriately lubricated according to producer guidelines to decrease rubbing and avoid early wear.

An additional crucial maintenance idea is to maintain the undercarriage tidy from dirt, rocks, and debris. Buildup in the undercarriage can speed up wear and corrosion, causing expensive repairs. Washing the undercarriage after procedure in severe conditions is suggested to avoid these problems.

Finally, monitoring and recording upkeep tasks can aid in developing a positive upkeep timetable. Maintaining comprehensive records of examinations, repair services, and substitutes can provide useful understandings right into the undercarriage's condition and performance in time, assisting in predicting and stopping possible failings. By following these maintenance ideas carefully, drivers can substantially increase the resilience and efficiency of undercarriage components in heavy machinery.

Selecting the Right Undercarriage Elements

Selecting proper undercarriage parts is crucial for maximizing the performance and longevity of heavy machinery. When it comes to choosing the right undercarriage parts, there are a number of factors to think about.

Additionally, considering the high quality and reputation of the maker is vital. Choosing reliable brand names understood for creating high-performance and resilient click resources undercarriage parts can considerably impact the general efficiency and long life of the equipment. Making certain that the components are compatible with the maker design and properly set up is crucial for ideal performance. By carefully selecting the ideal undercarriage parts, tools owners can improve performance, decrease downtime, and extend the life-span of their hefty machinery.

Study: Enhanced Performance With Durable Components

Including sturdy undercarriage components has demonstrated significant enhancements in equipment performance. One study involved a building company that updated its excavator's undercarriage parts to much more durable alternatives. The firm observed a noteworthy decline in downtime due to undercarriage maintenance, resulting in increased productivity and cost savings. The sturdy parts stood up to rough working problems, minimizing wear and tear dramatically.

In one more instance, a mining operation changed the undercarriage parts of its bulldozer with high-grade, resilient options. This button caused a remarkable renovation in the bulldozer's maneuverability and general performance. The maker could navigate difficult terrains much more effectively, causing improved functional performance and decreased gas intake.

Additionally, a logging business bought durable undercarriage parts for its forestry tools. The upgraded elements exhibited extended life expectancy and boosted resistance to abrasion from harsh terrain. As a result, the firm experienced reduced maintenance expenses and enhanced devices uptime, inevitably improving its lower line. These study highlight the concrete advantages of utilizing durable undercarriage parts in enhancing equipment efficiency and durability.

Verdict

In conclusion, using long lasting undercarriage components can substantially enhance performance and longevity of hefty machinery. Aspects such as appropriate maintenance and choosing the right parts play an essential role in taking full advantage of undercarriage sturdiness. By implementing these methods, businesses can lower downtime, boost efficiency, and eventually reduce operational prices. Study have shown that buying durable undercarriage components can lead to enhanced total efficiency and productivity in different sectors.

The effectiveness and performance of these parts can significantly influence the overall procedure click over here of machinery, making the choice of durable undercarriage parts an essential choice for supervisors and operators alike.Including resilient undercarriage components has actually demonstrated substantial improvements in machinery performance. These instance studies emphasize the substantial benefits of making use of resilient undercarriage parts in maximizing equipment performance and long life.

In conclusion, utilizing sturdy undercarriage components can dramatically more tips here enhance efficiency and durability of heavy machinery (undercarriage parts). Situation studies have actually revealed that investing in sturdy undercarriage components can lead to enhanced overall performance and productivity in various sectors

Report this page